InnuScience is launching a new eco-friendly micro fibre wash that provides full laundry power at 30°c - with the help of biotechnology. The life span of the cleaned micro fibre has doubled and reduces energy consumption by 70%. The results are: lower emissions of carbon dioxide and fewer micro-plastics (Which micro fibre is made of) in our oceans.

InnuScience is a global leader in commercial cleaning solutions based on biotechnology. Introduced with success to the UK market in 2009, InnuScience UK offers a full line of highly effective, eco-certified and non-toxic products to the cleaning and catering markets. They are the preferred supplier of biological cleaning products to Bunzl Cleaning & Hygiene Supplies and the official cleaning product supplier to Eco Schools UK. InnuScience is used with confidence on thousands of UK premises by the UK’s biggest cleaning companies and has a prestigious list of contracts in every sector served.

"We, in the cleaning industry who profit from the micro fibre products used today, also have a responsibility to reduce emissions of micro-plastics. The development of this new gentle Bio Wash Nu-Cycle N, cleaning at relatively low temperatures, is an example of what we can do. By taking a more sustainable path, we aim to shape the future of green cleaning," says Nick Winstone, Managing Director InnuScience UK.

Nu-Cycle N was piloted in the Swedish market for 2 years prior to its UK launch. Low washing temperature and pH neutral detergent reduces the emissions of micro-plastics. Micro fibre is a fabric of small plastic fibres that are intertwined. When washed at high temperatures, any broken plastic fibres are shattered and shed tiny plastic particles, micro-plastics. These get partially caught up in wastewater treatment plants. A study by IVL Swedish Environmental Research Institute and the Swedish Water in 2014 showed that a total of 30-70 million particles of micro-plastics per hour are discharged into the sea from a large Swedish treatment plants. We can influence this for the better by gentle washing and better management of micro fibre.

By lowering the washing temperature from 50°c to 30°c, it is possible to reduce energy consumption by 70%. InnuScience has developed a newly efficient washing cycle that shortens the washing period by up to 30%. In Sweden, there are about 120,000 washes every day with cloths and mops of professional cleaning, which corresponds to the electricity consumption of 14,000 households. In total, reduced energy consumption and reduced carbon emissions can have a significantly lower impact on both materials and climate.

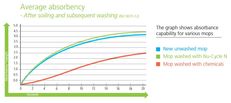

Washing with biotechnological products gives textiles both better absorption and improved cleaning results. Today's chemical detergents typically require high temperature and degrades the performance of micro fibre. Chemical detergents emulsify the grease and dirt from micro fibre, but it opens with the higher temperature and absorbs in the dirty water again. This leaves large residues of grease in the micro fibre after washing and makes it difficult for it to capture dirt and water.

"Today’s required high cleaning standards need micro fibre to be in optimal condition after every wash – mops are required to absorb water and remove dirt, like new after every wash. Tests show that mops and cloths that are washed with InnuScience’s Nu-Cycle N, keeps the same absorbency after washing as they had when they were new ", says Ellinor Niit, textile engineer for InnuScience Scandinavia.

Except where otherwise stated, content on this site is

licensed under a Creative Commons Attribution 3.0 License.

Except where otherwise stated, content on this site is

licensed under a Creative Commons Attribution 3.0 License.